The melting point of tungsten is the highest of all metal elements, the density (19. 3 g/cm) is very high, close to gold, tungsten hardness is also very high, such as tungsten carbide hardness is close to diamond.In addition, tungsten also has good electrical and thermal conductivity, small expansion coefficient and other characteristics, so it is widely used in alloy, electronics, chemical industry and other fields, among which cemented carbide is the largest consuming field of tungsten.

http://www.chtitanium.com/Tungsten

Alloy field:

Steel

The tungsten hardness of tungsten steel milling cutter is very high and the density of tungsten is close to that of gold, so it can improve the strength, hardness and wear resistance of steel. It is an important alloy element and is widely used in the production of various kinds of steel.Common tungsten containing steels include high speed steel, tungsten steel and tungsten cobalt magnetic steel with high magnetization and coercivity. These steels are mainly used in the manufacture of various tools, such as drill bits, milling cutters, wire drawing dies, negative and positive dies, etc.

Thermal strength and wear resistant alloy

Tungsten has the highest melting point and high hardness of all metals and is often used to produce thermal strength and wear resistant alloys.Alloys such as tungsten, chromium, cobalt, and carbon are often used to produce high-strength wear-resistant parts such as aeroengine valves, turbine impellers, and tungsten and other refractory metals (such as tantalum, niobium, molybdenum, etc.) Rhenium alloys are often used to produce parts with high thermal strength, such as air rocket nozzles, engines and so on.

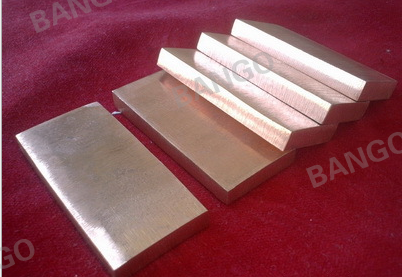

High specific gravity alloy

Because of its high density and high hardness, tungsten has become an ideal material for making high density alloys.These high specific gravity alloys are divided into w-ni-fe-w-ni-cuw-coc-cuw-wc-cuw-ag and other main series according to their composition characteristics and applications.This kind of alloy has the characteristics of high specific gravity, high strength, strong absorption ability of ray, large thermal conductivity, small coefficient of thermal expansion, good electrical conductivity, weldability and processability.Widely used in aerospace, aviation, military, oil drilling, electrical instrumentation, medicine and other industries, such as the manufacture of armour, radiator, rudder balance hammer and contact materials such as gate switches, circuit breakers, spot welding electrodes, etc.

http://www.chtitanium.com/Tungsten